ASCAMM celebrates a successful technical conference of molds

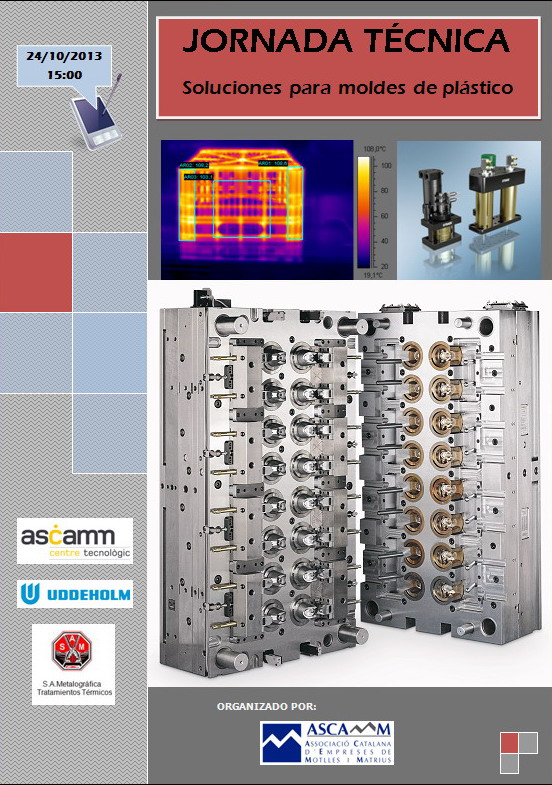

The conference “Solutions for plastic mold ” , organized by ASCAMM , was well attended and generated great interest among the participating companies , including manufacturers that had both plastic injection molds and plastic components manufacturers .

The session began with ” the mold of the future” by Alfonso Sánchez ASCAMM Foundation , who explained the latest developments in applied intelligence to mold design and embedded systems to optimize production of plastic components .

Ms. Lena Rahlén , Product Manager Uddeholms Plastic AB, presented the most important aspects when choosing a steel to build a mold, and the problems associated with the poor choice of a steel . He also gave an overview of the hardness and characteristics of steels used in the manufacture of plastic injection molds.

Mr . Andrea Castelli , Marketing Manager of Materion Brush GmbH, presented different solutions to the use of high conductivity alloys into molds , in order to reduce cycle time and time to resolve some of the most common problems in plastic parts such as lines welding , deformation after injection , trademarks, etc. .

Mr . Daniel Vidal , Commercial Technical Uddeholm Spain , introduced the standardized Strack Norma, highlighting accessories like drag extractors , moving elements , ejectors double layer sliding cylinders unscrew , etc. .

Finally, Mr. Francisco Borrego , SA Metalografica Technical Director, introduced heat and surface treatments to optimize the life of plastic injection mold .

The event was held at the Hotel Eurostars Parc Valles, with ASCAMM , and attended by over 50 professionals.

ASCAMM continues working to offer new workshops of interest to the die and mold industry .

More information:

Mr. Domènec Pijuan